Bringing Physical AI to Furniture Manufacturing – how Vilniaus baldai in Lithuania is rethinking physically demanding work

Bringing Physical AI to Furniture Manufacturing – how Vilniaus baldai in Lithuania is rethinking physically demanding work

At Vilniaus baldai, supporting employees is a prerequisite for long-term performance. By introducing Exia exoskeletons into daily production, the company reduces physical strain, promotes healthier movement and makes demanding industrial jobs more attractive – without disrupting established workflows.

At Vilniaus baldai, supporting employees is a prerequisite for long-term performance. By introducing Exia exoskeletons into daily production, the company reduces physical strain, promotes healthier movement and makes demanding industrial jobs more attractive – without disrupting established workflows.

Copy link to share

Copy link to share

Link copied to clipboard !

Copy link to share

Link copied to clipboard !

How Vilniaus baldai is making physically demanding work safer and more sustainable

In furniture manufacturing, physical strain is not an exception. It is part of the daily routine.

Lifting panels, handling components, working at varying heights and performing repetitive movements place continuous stress on the body. As in many industrial production environments, the lower back bears much of this load – shift after shift.

One company addressing this challenge head-on is Vilniaus baldai, one of Lithuania’s leading furniture manufacturers.

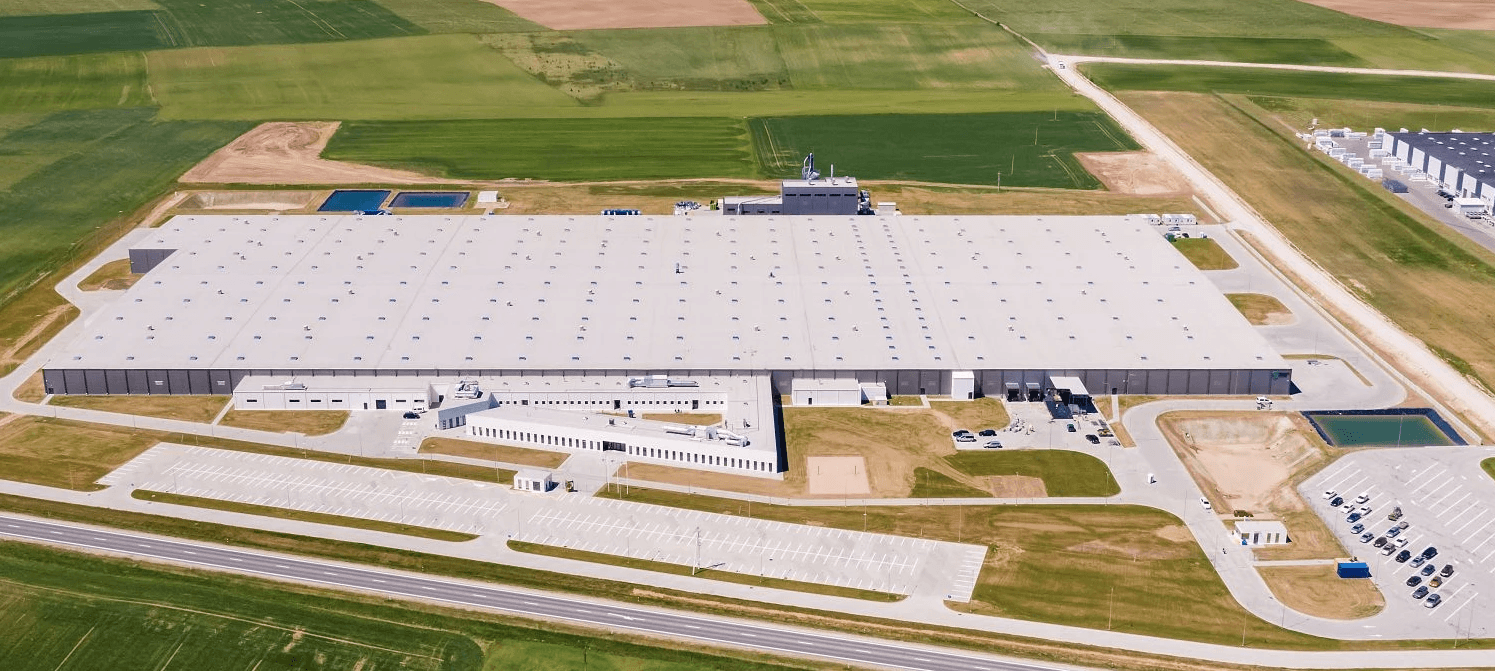

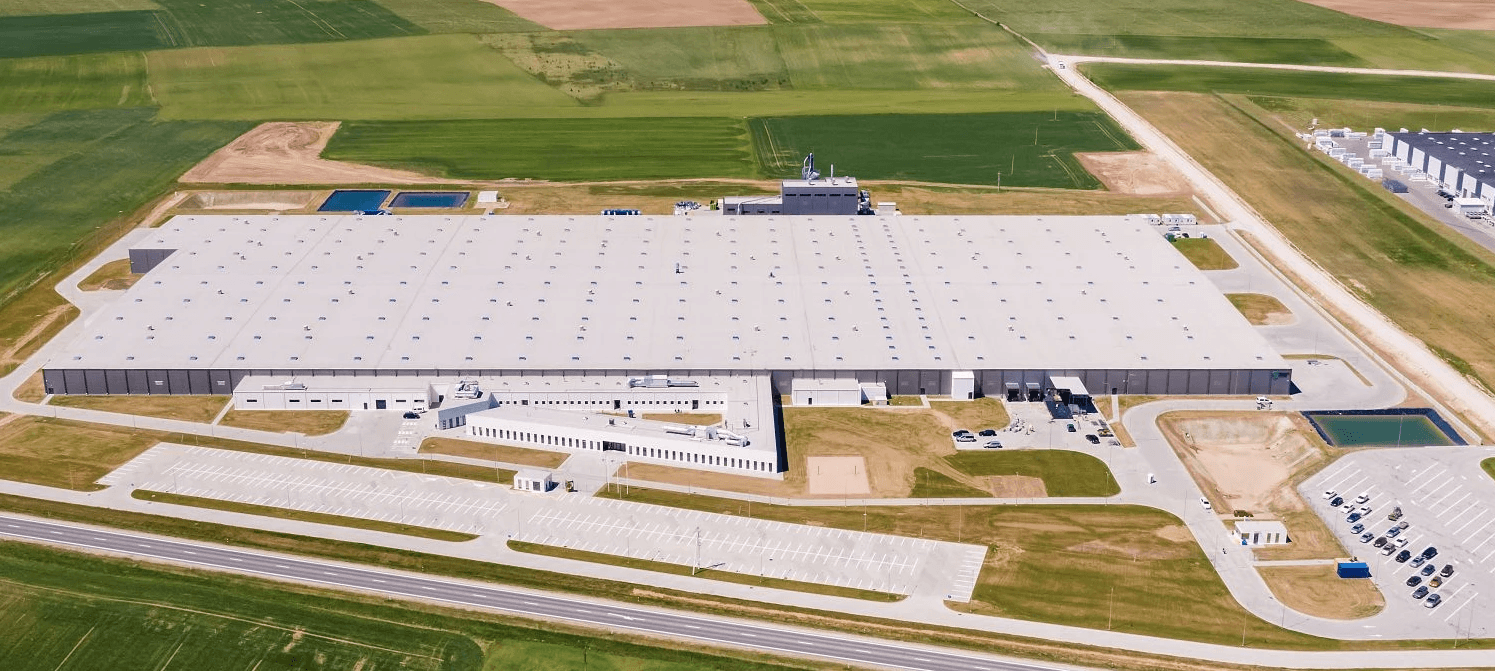

With more than 140 years of experience in the production of lightweight, modular furniture, Vilniaus baldai stands for consistent quality at industrial scale. Operating a state-of-the-art production facility spanning more than 73,000 square metres, the company combines efficiency with a strong sense of responsibility towards its workforce. Investing in safer, more attractive workplaces is not only a matter of employer responsibility – it is a prerequisite for long-term performance.

Intelligent support for physically demanding work

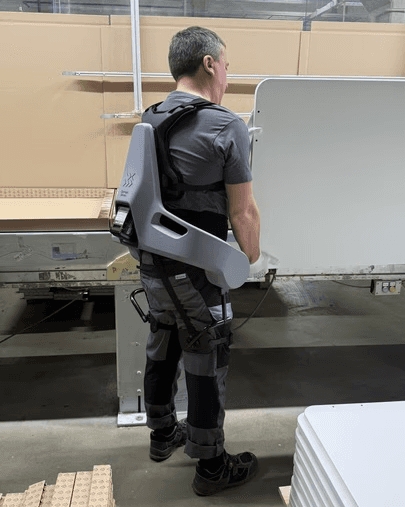

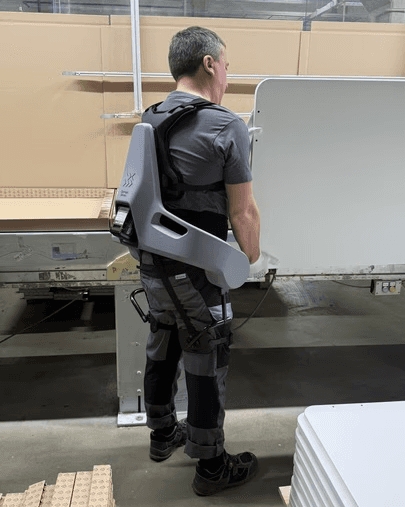

By deploying Exia exoskeletons from German Bionic, Vilniaus baldai is bringing Physical AI directly into furniture production.

The Exia exosuit provides intelligent, data-driven support for physically demanding lifting and handling tasks. It actively reduces strain on the lower back, supports healthier movement patterns and helps employees manage repetitive loads more effectively – all without restricting mobility or disrupting established workflows on the shop floor.

Measurable impact in daily operations

The deployment of Exia exoskeleton technology at Vilniaus baldai delivers tangible benefits in everyday production:

Noticeable relief for employees during repetitive lifting and lowering tasks, with up to 38 kg of support per lift

Safer and more sustainable working conditions across daily operations

Higher productivity through reduced fatigue and physical strain

Investing in people and performance

High-quality production, employee well-being and the responsible use of technology go hand in hand.

By reducing physical strain and investing in modern, human-centred technology, companies can better protect their workforce while making industrial jobs more attractive. This not only supports long-term employee retention, but also strengthens recruitment in an increasingly competitive labour market.

For Vilniaus baldai, the integration of Physical AI is a clear statement: sustainable performance starts with supporting the people who make it possible.

How Vilniaus baldai is making physically demanding work safer and more sustainable

In furniture manufacturing, physical strain is not an exception. It is part of the daily routine.

Lifting panels, handling components, working at varying heights and performing repetitive movements place continuous stress on the body. As in many industrial production environments, the lower back bears much of this load – shift after shift.

One company addressing this challenge head-on is Vilniaus baldai, one of Lithuania’s leading furniture manufacturers.

With more than 140 years of experience in the production of lightweight, modular furniture, Vilniaus baldai stands for consistent quality at industrial scale. Operating a state-of-the-art production facility spanning more than 73,000 square metres, the company combines efficiency with a strong sense of responsibility towards its workforce. Investing in safer, more attractive workplaces is not only a matter of employer responsibility – it is a prerequisite for long-term performance.

Intelligent support for physically demanding work

By deploying Exia exoskeletons from German Bionic, Vilniaus baldai is bringing Physical AI directly into furniture production.

The Exia exosuit provides intelligent, data-driven support for physically demanding lifting and handling tasks. It actively reduces strain on the lower back, supports healthier movement patterns and helps employees manage repetitive loads more effectively – all without restricting mobility or disrupting established workflows on the shop floor.

Measurable impact in daily operations

The deployment of Exia exoskeleton technology at Vilniaus baldai delivers tangible benefits in everyday production:

Noticeable relief for employees during repetitive lifting and lowering tasks, with up to 38 kg of support per lift

Safer and more sustainable working conditions across daily operations

Higher productivity through reduced fatigue and physical strain

Investing in people and performance

High-quality production, employee well-being and the responsible use of technology go hand in hand.

By reducing physical strain and investing in modern, human-centred technology, companies can better protect their workforce while making industrial jobs more attractive. This not only supports long-term employee retention, but also strengthens recruitment in an increasingly competitive labour market.

For Vilniaus baldai, the integration of Physical AI is a clear statement: sustainable performance starts with supporting the people who make it possible.